Type C

Reflecting on the tree’s journey

TITLE

「FILLET」

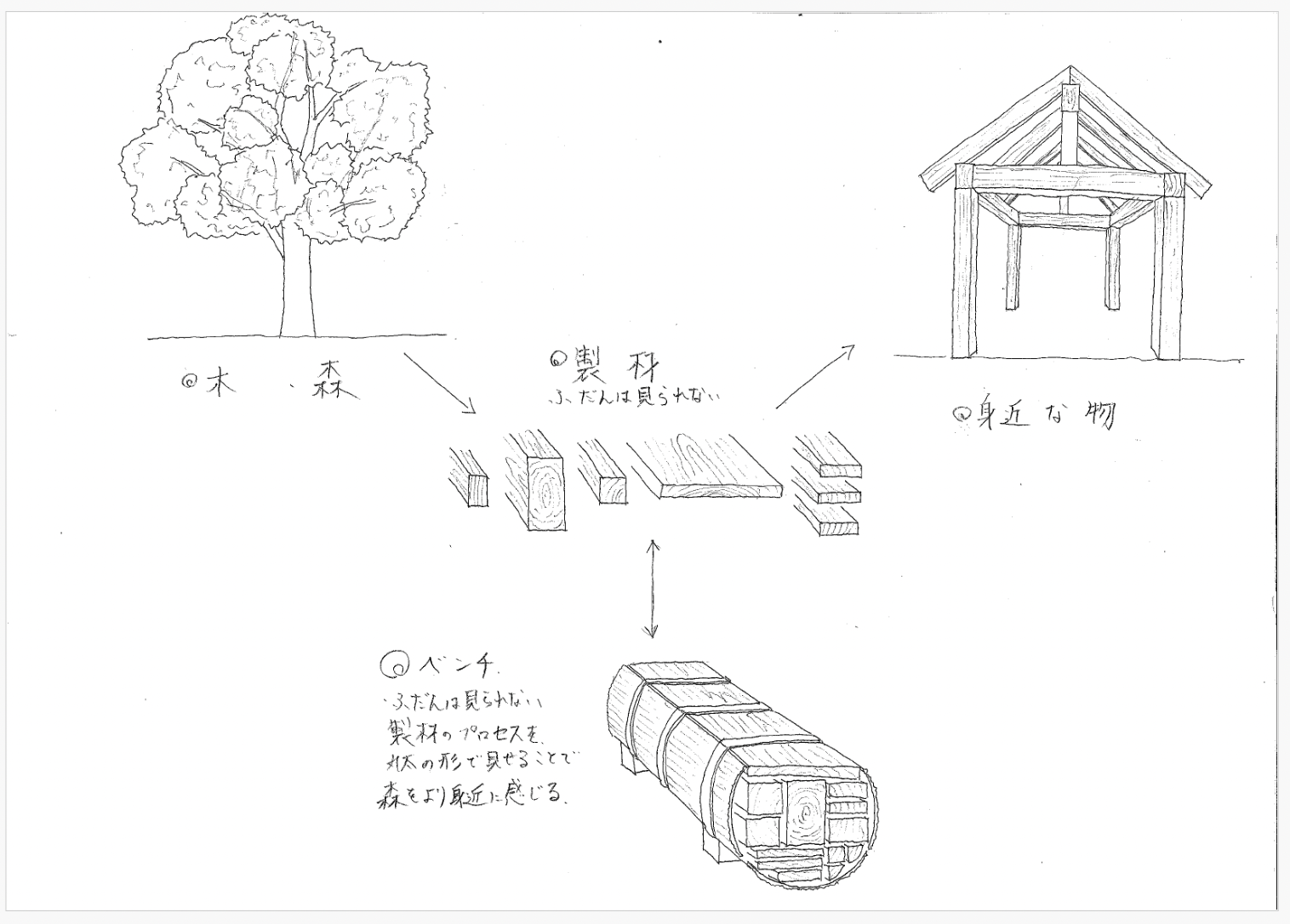

A large log is milled into building materials, then reassembled into a bench that echoes the original form of the tree. The drying process—during which the wood naturally cracks and warps—is carried out on-site at the Expo venue, becoming part of the bench’s evolving story.

Designed by

Sano Fumihiko

DESIGNER’S PROFILE

Born in Nara Prefecture in 1981, he apprenticed as a carpenter under Nakamura Sotoji, a master of sukiya architecture. After completing his apprenticeship, he gained experience at design studios and firms including PPMOBLER, before establishing his own practice in 2011. In 2016, he travelled to 16 countries as a Japan Cultural Envoy, engaging in a wide range of cross-cultural projects. Drawing on the techniques and sensibilities cultivated through these experiences, he now works across disciplines—from architecture to art.

Designer’s Reflection

A tree may live for decades in the forest, but compared to that lifespan, the Expo is over in the blink of an eye. Once felled, the tree begins a second life as “material,” eventually becoming part of a building or structure. During the transition, this bench offers a temporary resting form—an in-between state. Once the Expo ends, the wood will embark on its next journey, perhaps as part of an architectural piece. I like to imagine us resting momentarily against the tree in this fleeting form, before it moves on once again.

Process of Creation

2024.4-2025.3

Sano, whose practice spans architecture and spatial design, shared his thoughts:“Once trees are turned into square timber or building materials, you can’t tell they’re from Osaka. I didn’t just want to ‘use the wood’; I wanted to connect Expo visitors to the forests of Osaka.”

The design went through several iterations before reaching its final form.

Four Osaka-grown cedar logs, each approximately 50 cm in diameter and 180 cm in length, were selected.

01/02: The wood was milled to a size and shape suitable for future architectural use. 03: After rough sawing, wood is typically dried until the moisture content drops below 10%. However, because it is difficult to predict the extent of cracking and warping during drying, we opted to kiln-dry it to about 15% moisture for safety.

01/02: The timber emerges from the kiln. 03: Roughly assembled, the wood retains its cracks and marks. From here, the remaining drying process will continue at the Expo site.

Other Benches